- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Exploring Industry-Specific Use Cases for the Best Trunnion Mounted Ball Valve: A Comprehensive How-to Guide

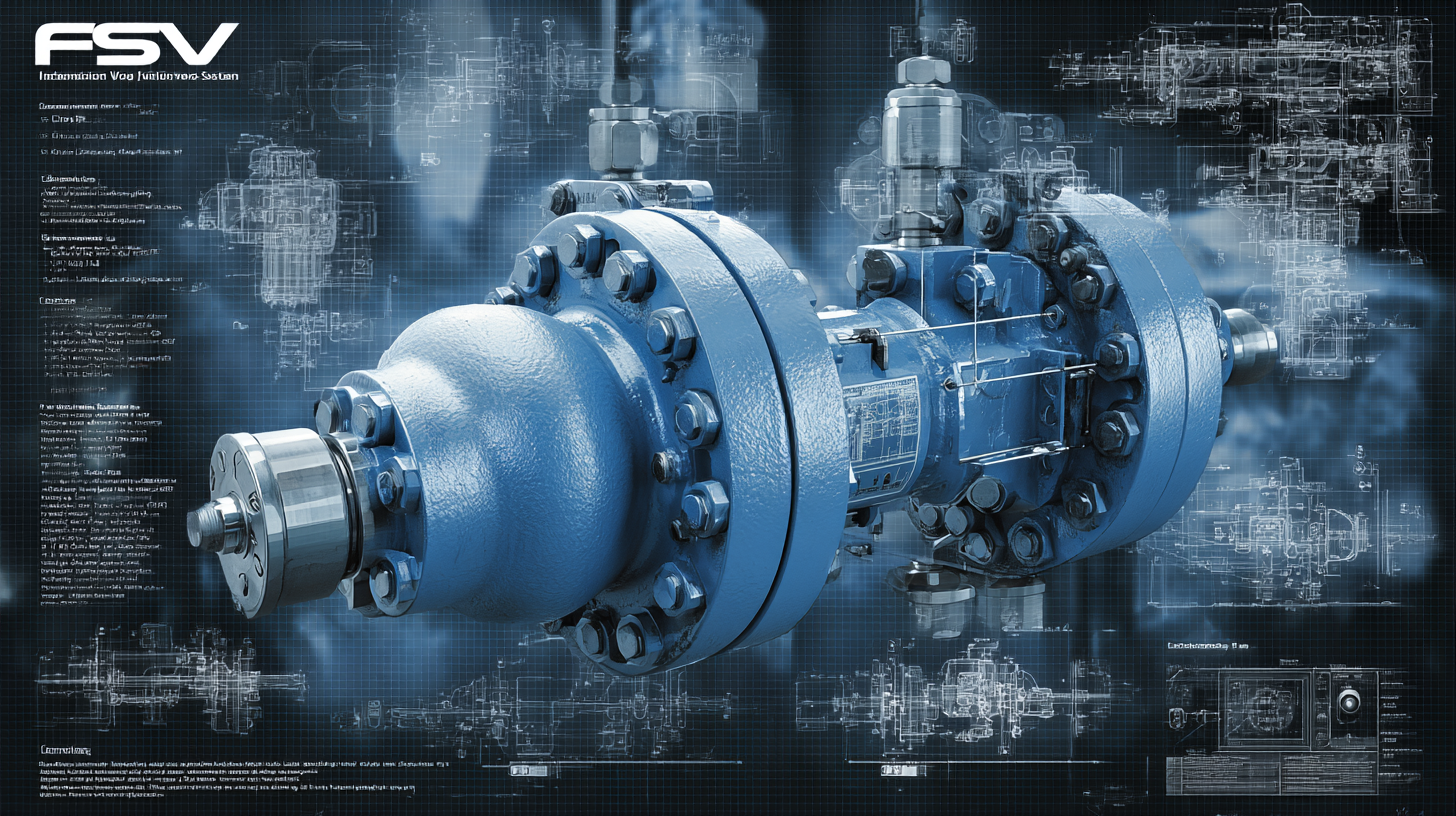

As industries strive for greater efficiency and sustainability in their operations, the importance of high-performance components like the Trunnion Mounted Ball Valve has never been more pronounced. According to a recent market research report by Research and Markets, the global valve market is projected to reach $93.7 billion by 2025, with significant growth driven by advancements in automation and smart technologies. The Trunnion Mounted Ball Valve, known for its reliable sealing capabilities and ability to withstand high pressures, plays a crucial role in sectors such as oil and gas, water treatment, and chemical processing. This comprehensive guide aims to explore specific use cases of Trunnion Mounted Ball Valves across various industries, providing insights into their operational advantages and best practices for implementation. By understanding the nuances of these applications, businesses can enhance their operational efficiency and contribute to the industry's technological evolution.

Key Features and Benefits of Trunnion Mounted Ball Valves in Various Industries

Trunnion mounted ball valves are essential in various industries due to their distinctive design and operational advantages. These valves provide superior sealing capabilities, which are crucial in high-pressure applications like oil and gas extraction and chemical processing. One key feature is their ability to minimize seat wear, as the ball is fixed and does not pivot on its seat, allowing for extended service life and reduced maintenance costs. This durability makes them ideal for demanding environments.

Trunnion mounted ball valves are essential in various industries due to their distinctive design and operational advantages. These valves provide superior sealing capabilities, which are crucial in high-pressure applications like oil and gas extraction and chemical processing. One key feature is their ability to minimize seat wear, as the ball is fixed and does not pivot on its seat, allowing for extended service life and reduced maintenance costs. This durability makes them ideal for demanding environments.

When selecting a trunnion mounted ball valve, consider the operating conditions of your application. For example, ensure that the materials used can withstand the specific temperature and pressure ranges relevant to your industry. Additionally, verify that the valve's size and flow characteristics align with your system's requirements.

Tip: Regular maintenance checks can significantly extend the lifespan of your valve. Monitor for any signs of leakage and ensure that actuators and seals are functioning optimally. Also, keep a detailed log of maintenance activities to identify patterns that could indicate emerging issues before they progress into costly failures.

Applications of Trunnion Mounted Ball Valves in Oil and Gas Sector

Trunnion mounted ball valves play a pivotal role in the oil and gas sector, providing reliable control over the flow of liquids and gases in various applications. These valves are designed to withstand high pressure and temperature fluctuations, making them ideal for upstream and downstream operations where safety and efficiency are paramount. With their unique design, trunnion valves minimize torque and enhance seal integrity, reducing the risk of leaks and ensuring reliable performance in critical processes such as drilling, production, and transportation.

As the global ball valve market is projected to reach USD 22.5 billion by 2033, driven by an estimated CAGR of 4.7%, the demand for high-performing valves in the oil and gas industry continues to grow. Trends indicate an increasing emphasis on automation and smart valve technology, which enhances control and monitoring capabilities. This shift not only improves operational efficiency but also aligns with the industry's push towards sustainability and reduced environmental impact. The integration of advanced materials and manufacturing techniques further supports the reliability and longevity of trunnion mounted ball valves, solidifying their role as essential components in modern oil and gas infrastructure.

How to Choose the Right Trunnion Mounted Ball Valve for Your Specific Needs

When selecting the right trunnion mounted ball valve for your specific needs, it’s essential to consider the operational conditions and application requirements. According to a report by Grand View Research, the global ball valve market size is expected to reach USD 12 billion by 2025, driven largely by increasing demand in industries such as oil and gas, water management, and power generation. Given the varied applications, understanding the characteristics that differentiate trunnion mounted ball valves from other types is crucial. These valves are preferred for their ability to handle high pressure and temperature, providing enhanced stability and reduced torque during operation.

Another key factor to consider is material compatibility. The right valve material must align with the media being transported, especially in sectors like chemical processing, where aggressive substances can cause rapid degradation. A study by MarketsandMarkets suggests that by 2027, the chemical industry will account for approximately 30% of the ball valve market, underlining the importance of selecting materials such as stainless steel or various alloy compositions that offer corrosion resistance and durability. By assessing these critical parameters—operational requirements and material selection—industry professionals can ensure optimal performance and longevity of trunnion mounted ball valves tailored to their specific applications.

Comparative Analysis: Trunnion Mounted vs. Floating Ball Valves

When considering the choice between trunnion mounted and floating ball valves, it's essential to analyze their respective use cases and performance characteristics within various industries. Trunnion mounted ball valves are often preferred in high-pressure, high-temperature applications due to their ability to handle larger pipe sizes and their reduced torque requirements. This type of valve generally provides better sealing performance under extreme conditions, making it suitable for industries such as oil and gas, where reliability is paramount.

On the other hand, floating ball valves are typically used in lower-pressure applications and are known for their ease of operation and cost-effectiveness. The floating design allows the ball to position itself based on the flow, providing a reliable seal without requiring heavy mechanical components. This makes them an ideal choice for applications in water treatment and chemical processing. According to a market analysis, the global ball valves market is expected to reach USD 22.5 billion by 2033, growing at a CAGR of 4.7%. This growth reflects the increasing adoption of both trunnion mounted and floating ball valves as industries seek solutions capable of ensuring efficiency and safety in their operations.

Maintenance Best Practices for Maximizing the Lifespan of Trunnion Mounted Ball Valves

When it comes to maintaining trunnion mounted ball valves, implementing best practices is essential for maximizing their lifespan and ensuring optimal performance. Regular inspection is the foundation of effective maintenance. It is vital to check for any signs of wear, corrosion, or leakage at the valve seals, as these issues can compromise functionality. Additionally, maintaining a clean environment around the valve helps prevent debris accumulation that might interfere with its operation.

Another critical aspect of maintenance is lubrication. Applying the appropriate lubricant to the valve's moving parts can significantly reduce friction and wear, allowing for smoother operation and extending the valve's lifespan. It's important to follow the manufacturer’s guidelines for lubrication frequency and type to avoid any potential damage. Finally, conducting periodic performance tests helps identify any deviations from normal operation, allowing for timely interventions before issues escalate. By adhering to these maintenance best practices, users can ensure their trunnion mounted ball valves operate efficiently for many years.